Maps, fuel injection, and Tuning for Cannondales/ATK/Sagem 1000

Basics

Cannondales fuel injection is anything but unique, except for the

fact that it is on a dirt bike. The computer is actually an automotive

unit, and the fuel pump also fits a Ford Ranger! This is the way it works,

conceptually;

The operating system in the computer is similar to DOS in your

computer, but in these units it comes in a .hex file, so it is called the

‘OP CODE’ or the HEX CODE’. The computer actually does very little computing.

What it does do is get inputs from the sensors on the motor; air temperature,

coolant temperature, air pressure, crankshaft position, throttle opening

in %. It calculates engine speed based on the last few crankshaft positions,

then uses this calculated RPM and the throttle opening to find a value

for fuel delivery and spark advance from a look up table; commonly called

a ‘MAP’. The value that is looked up in the map is then adjusted

for the other variables (temps and pressure). This is done for every engine

cycle, and when the time is right, the fuel injectors are opened for the

appropriate period of time, and the ignition is fired at the precise moment

that it is needed. Then the cycle repeats.

The D&M kit is the owners tool that allows you to fiddle with

this stuff. You will be doing your jetting with it, you can troubleshoot

with it, and you can change maps with it. Here is a spreadsheet

(thanks, Radical Ron!!) that details what the maps look like. It includes

3 maps, that of the E, C, and X model motorcycles. And if you like that

kind of stuff, here is a spreadsheet

that compares the C and E maps.

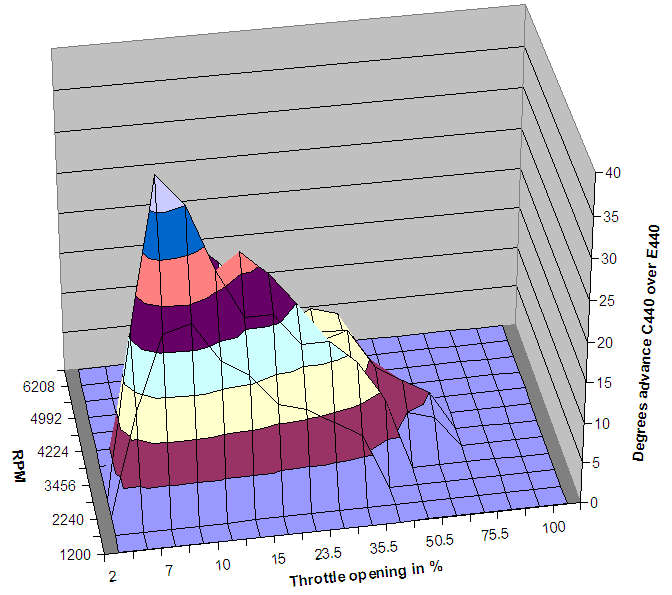

The fuel delivery is identical, and not

charted here. The only difference is the ignition advance, which is detailed

and graphed. There is no difference at all from 75% throttle and up, and

above about 4500 RPM. The picture at the right is a chart of the ignition

difference between the C and E. Note that the chart covers only rpm range of

1200 to 6200 rpm, there are no differences outside of this zone. What this means is that the E map will give you all

of the power the C map will, but with smoother response at the smaller

throttle openings.

The fuel delivery is identical, and not

charted here. The only difference is the ignition advance, which is detailed

and graphed. There is no difference at all from 75% throttle and up, and

above about 4500 RPM. The picture at the right is a chart of the ignition

difference between the C and E. Note that the chart covers only rpm range of

1200 to 6200 rpm, there are no differences outside of this zone. What this means is that the E map will give you all

of the power the C map will, but with smoother response at the smaller

throttle openings.

Maps

The most popular and fun thing to do with the D&M kit is to change

the map. There are a number of maps available for the downloading at ‘Cannondaler.Com’,

thanks to the ultimate ‘dale enthusiast Jim. The X map, designated by it’s

filename 01XXX.ccf, is the official MX map. There is also a C map, an E

map, and the S map. The X and S maps are identical, except that the S maps

has a more aggressive T/S (throttle sensitivity). The official maps all

use a T/S of 150 except for the S map as mentioned above. What a T/S of

150 means is that when the throttle is moving towards more open, the injected

fuel value will be compensated by the T/S in percent; so the mixture will

be 150% of calculated while the throttle is moving. This has a delaying

effect on the motors response, which was added after many riders complained

about the incredibly quick throttle response of the original bikes.

So, without consideration of the throttle sensitivity, there are basically two

maps from the factory; the X/S maps, and the C/E maps. The X/S are pretty

easy off the bottom, then rage out to the limits of the motor. The C/E

map is most powerful at the lower RPMs, then much more mild up on top to

conserve fuel and to be easier to ride on the longer cross country races.

The C is slightly more aggressive below 4000 RPM and below 65% throttle

opening for the dryer cross country races. The X/S, E, and C maps are all

available at ‘Cannondaler.Com’ with T/S settings from 110 to 150 in steps

of 10.

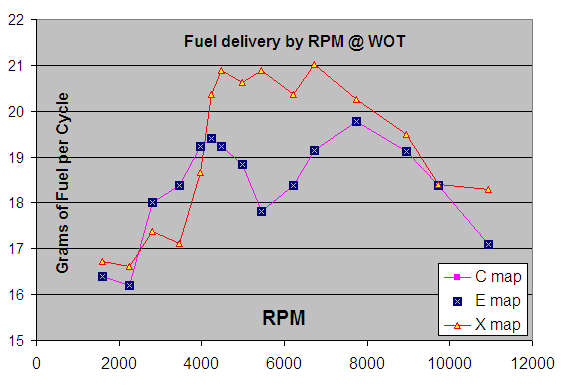

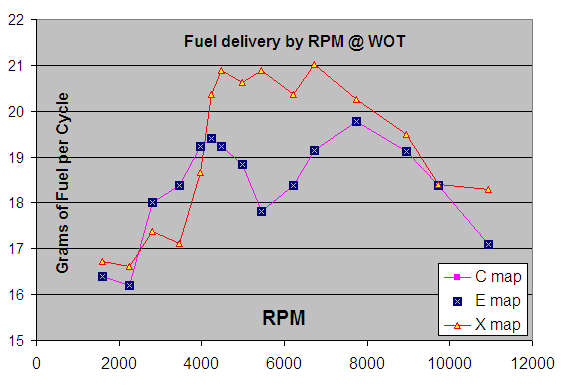

The next step, then was to fiddle with the maps.

The chart you see to the right is a graphic representation showing how much fuel

is delivered at what RPM for the two basic map types. The ignition curve in each

map is optimized for the amount of fuel that will be delivered.

The first breakthrough

was when Radical Ron put together an experimental map for me, the HarryMoto

Combo map. I asked him to try the E map up to 4000 RPM, and then patch

in all the numbers from the X map. Combined with the T/S of 110, this is

the most aggressive map for the ‘dale. Later on GP suggested using the

C map for the bottom end, and the GP Combo map was born. The combo maps

are identical at wide open throttle, but the GP map is slightly more aggressive

below 4000 RPM and below 65% throttle opening. Loading a map takes about

two minutes with the D&M kit, so it shouldn’t be hard to plug in some

maps and see what you like. The combo maps are also available at ‘Cannondaler.Com’,

free for the downloading.

Additionally, if you wish to help preserve your Cannondale crank for the

duration of your ownership, here are links to the '10k' maps. These are the

HarryMoto Combo maps with the rev limiter set to 10,000 rpms. This matches the

design limit of the stock bearings. <Note: it turns out that the 10K rating on

the bearings is in GREASE, not in an oiled application. I still run a lowered

rev limit, but I'm using 11K now.> The factory rev limiter setting is

11,800 rpm.

HarryMoto Combo 10K 110

HarryMoto Combo

10K 120

HarryMoto Combo

10K 130

HarryMoto Combo

10K 140

HarryMoto Combo

10K 150

And one more map that I made

for my daughter, the 'Amber Moto map'. It's the leanest part of the two maps

above with the rev limiter set at 7000. It's still a handfull for young riders,

but more managable and the ridiculous rev limit keeps the speed from building

too quickly if things get out of hand. It's terrible to ride, you hit the

limiter as soon as you twist the throttle!

Amber Moto Combo 7K 150

Jetting

This isn’t your daddy’s thumper. Jetting isn’t the same anymore,

so if you know what you are doing with brass that will be just a little

help in jetting your ‘dale. Luckily they don’t need jetting like a carbureted

bike does. Changes in the weather, changes in altitude, running really

fast or really slow… it just doesn’t matter, the EFI compensates for all

that. You may need to jet it because the factory sent them out pretty rich

for the most part, or you may have chopped the restrictive cones out of

the exhaust system. For whatever reasons, when you jet this bike you will

be fooling with two values; ‘OFFSET’ and ‘FLOW’. The flow is just what

it sounds like; flow through the fuel injectors. The offset adjusts for

how long it takes for the flow to get up to speed when the injector opens.

We’re talking milliseconds here, so it certainly matters. Flow is how many

milligrams per minute comes out of the injectors. Offset is how many milligrams

of fuel will be missing from a 2.5 millisecond shot from the injectors due to

the opening time of the injector,

as compared to a simple flow times time calculation. If you lower the offset,

you tell the computer that there is less fuel missing on a short shot and

it will compensate by making things leaner for the shorter duration pulses

of the injectors. If you lower the flow value, you are telling the computer

that the injectors are flowing less and it will compensate by making things

richer right across the board. Many folks will increase the flow by 1%

and take .1 to .2 off of the offset to get the mixture right with everything

stock.

To actually jet the thing, you can set the idle to 2100 and then

note the throttle position. Adjust the offset by .1, then set the idle

again and note the throttle position. The offset setting that gives you

the lowest throttle position to maintain 2100 RPM is the optimum idle setting.

You might go back .1 richer from there to get a more steady setting, like

we used to do when we were turning pilot screws and changing pilot jets.

To adjust the main jet, so to speak, you will have to resort to the WOT

runs and then read the spark plug. Not fun, as the spark plug is pretty far down

in there. Sort of makes you miss the old two-stroke, getting that spark plug

out! The tricky part here is that the flow effects the offset a lot, and the

offset effects the flow a little. You can do the main jet first, and minimize

the effects of the second adjustment. You can also use the

spreadsheet to see exactly what effects the adjustments

will have.

Here is

an example shot of the flow/offset spreadsheet. In this example the flow was

2400 from the factory, and the offset was .70. The bike in the example has had

the flow set to 2350 and the offset set to .6. The original fuel delivery would

be on the 100% line in the middle of the chart. The effect of each change is

charted, so you can see that the offset is a non-linear function and the flow is

quite linear. Another important thing to consider is that the effects are not

based on RPM, but rather on the length of the injector pulse in milliseconds.

It's not quite the same, check the example above to see the injector times at

different RPMs.

Here is

an example shot of the flow/offset spreadsheet. In this example the flow was

2400 from the factory, and the offset was .70. The bike in the example has had

the flow set to 2350 and the offset set to .6. The original fuel delivery would

be on the 100% line in the middle of the chart. The effect of each change is

charted, so you can see that the offset is a non-linear function and the flow is

quite linear. Another important thing to consider is that the effects are not

based on RPM, but rather on the length of the injector pulse in milliseconds.

It's not quite the same, check the example above to see the injector times at

different RPMs.

You can download the spreadsheet

to get a look at the changes you are making to YOUR bike and the effect they have on

the mixture in different areas. Just input your flow/10 (as in the example,

2400/10 = 240) and the offset. There are also blocks for the flow and offset

you are considering, the ones with 0.6 and 2350 in the example. The chart shows the difference between what you input

originally and what you input as the new settings. Remember that the original

settings are represented as the 100% line, and the changes are shown in percent

from that baseline. Good luck, and use your

common sense; it you run it too lean, you WILL burn it up!!

Troubleshooting

Obviously, this is a more advanced subject. The D&M tool will tell

you what everything reads, report faults, and will allow you to replace

a corrupted hex code. It will not tell you what it means; it only reports

the values. Check out the forums at ‘Cannondaler.Com’ to get some experienced,

professional (and amateur) help!

Gearing

If you like fooling with spreadsheets, you'll love the Gearing

& thrust spreadsheet! This charts speed/RPM/gear, and calculates

how hard the rear wheel pushes on the ground to move you forward from the

only dyno chart I've been able to find. This is all based on a C-440, and

I'm not sure about the dyno information. Anyone who has a decent dyno chart,

PLEASE email it to me at

DynoChart@HarryMoto.Com!!Tap and Die #'s

For those of you who have actually made it this far, here is a spreadsheet

that details what drill to use when you have to make a threaded hole. I've

found it to be very useful!

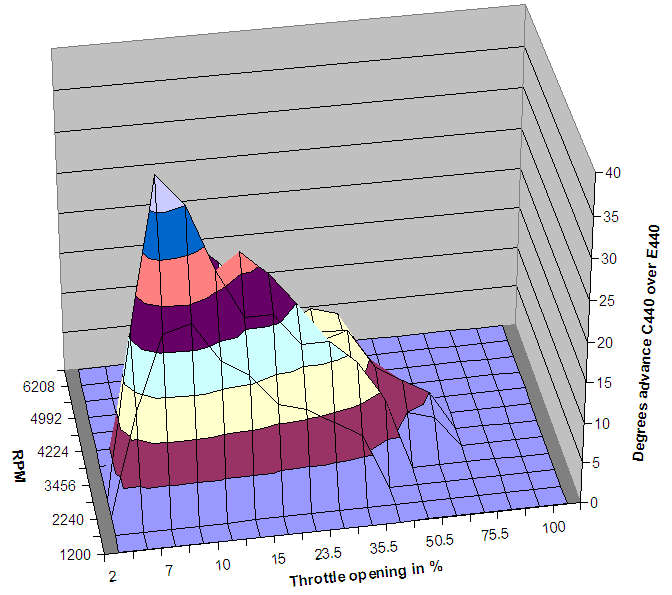

The fuel delivery is identical, and not

charted here. The only difference is the ignition advance, which is detailed

and graphed. There is no difference at all from 75% throttle and up, and

above about 4500 RPM. The picture at the right is a chart of the ignition

difference between the C and E. Note that the chart covers only rpm range of

1200 to 6200 rpm, there are no differences outside of this zone. What this means is that the E map will give you all

of the power the C map will, but with smoother response at the smaller

throttle openings.

The fuel delivery is identical, and not

charted here. The only difference is the ignition advance, which is detailed

and graphed. There is no difference at all from 75% throttle and up, and

above about 4500 RPM. The picture at the right is a chart of the ignition

difference between the C and E. Note that the chart covers only rpm range of

1200 to 6200 rpm, there are no differences outside of this zone. What this means is that the E map will give you all

of the power the C map will, but with smoother response at the smaller

throttle openings.

Here is

an example shot of the flow/offset spreadsheet. In this example the flow was

2400 from the factory, and the offset was .70. The bike in the example has had

the flow set to 2350 and the offset set to .6. The original fuel delivery would

be on the 100% line in the middle of the chart. The effect of each change is

charted, so you can see that the offset is a non-linear function and the flow is

quite linear. Another important thing to consider is that the effects are not

based on RPM, but rather on the length of the injector pulse in milliseconds.

It's not quite the same, check the example above to see the injector times at

different RPMs.

Here is

an example shot of the flow/offset spreadsheet. In this example the flow was

2400 from the factory, and the offset was .70. The bike in the example has had

the flow set to 2350 and the offset set to .6. The original fuel delivery would

be on the 100% line in the middle of the chart. The effect of each change is

charted, so you can see that the offset is a non-linear function and the flow is

quite linear. Another important thing to consider is that the effects are not

based on RPM, but rather on the length of the injector pulse in milliseconds.

It's not quite the same, check the example above to see the injector times at

different RPMs.